Our company can design and manufacture many types of belt conveyer suitable for use of underground mine, surface, port and power plant. And we can provide professional technical support for different customers.

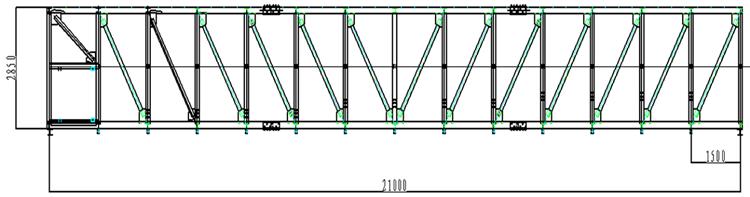

We can design telescopic gate road conveyer, and other belt conveyers for maingate, main shaft (including steeply inclined), surface coal washing plant system belt conveyer (including reversible bunkering and manual conveyer), loading station belt conveyer. Currently, we are making research and development on advancing and semi-advancing belt conveyer for open cast mine.

Technical Strength

Professional engineer team

Our technical center is composed of 1st institute, 2nd institute, 4th institute, Standardization Department, Scientific & Technological Development Department, Technology Institute and Electrical Control Institute. And we have a team of 161 professional designing, processing and manufacturing engineers and technicians for .

Complete Theory System

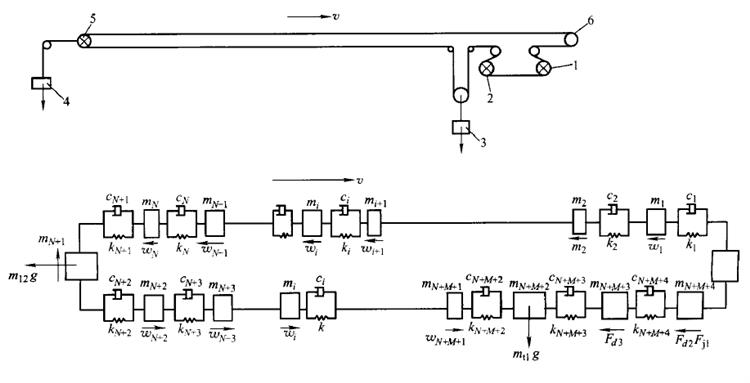

During the process of startup and braking, the dynamic action of the belt conveyer is complex because the speed and acceleration varies very much. Therefore, the research of the impact on system stability of instantaneous dynamic response and drive force has been conducted to optimize the designing plan of startup, braking and dynamic features. Dynamic analysis is conducted according to technical parameters, working status, performance requirement and modeling of telescopic belt conveyer to make the overall layout of the belt conveyer and components meet the static and dynamic optimization requirement, through which the life of components like drive device, belt, roller, drum and the whole machine can be maximized, and the economical requirement can be fulfilled.

Dynamic analysis modeling

Structure analysis means

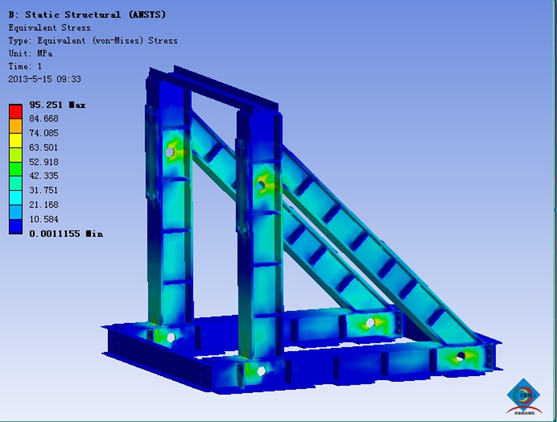

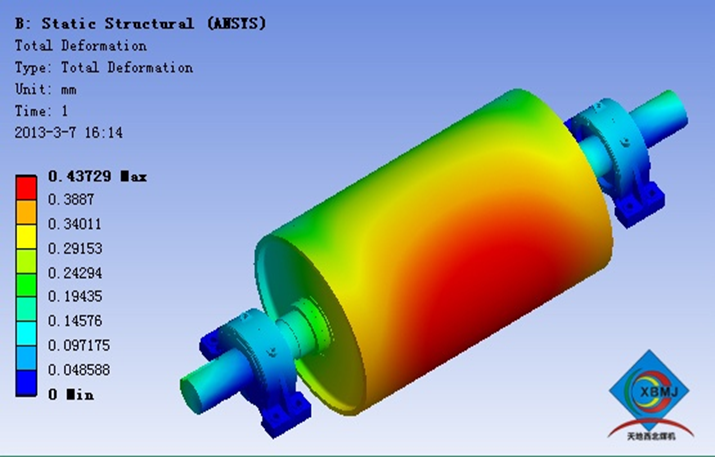

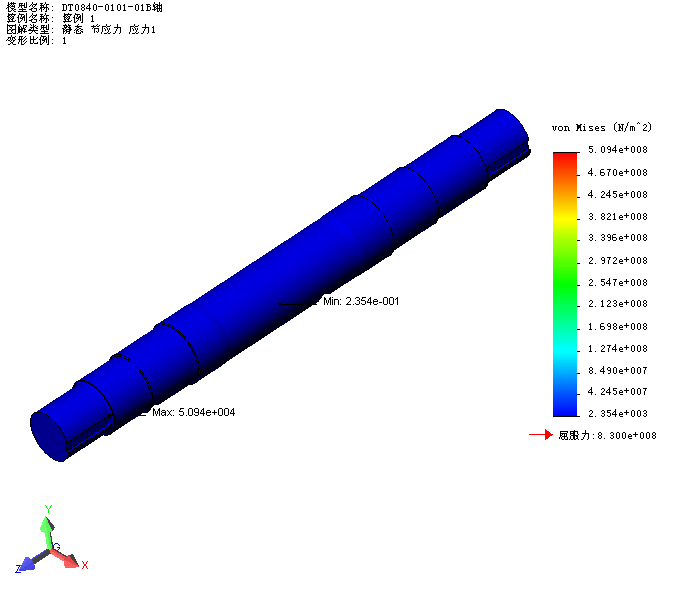

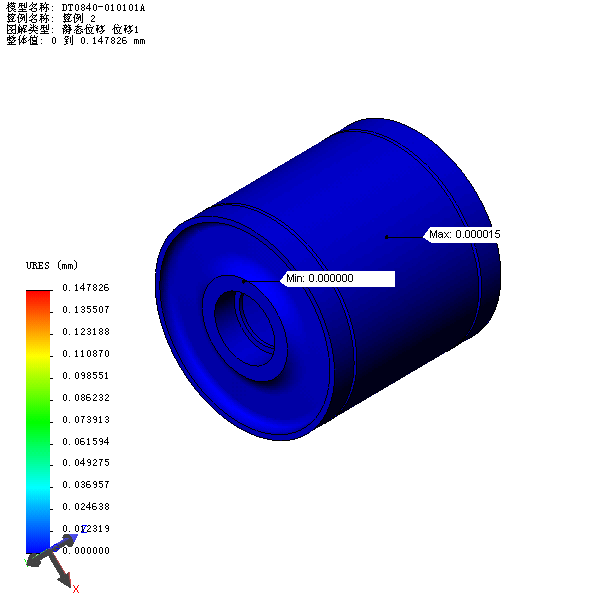

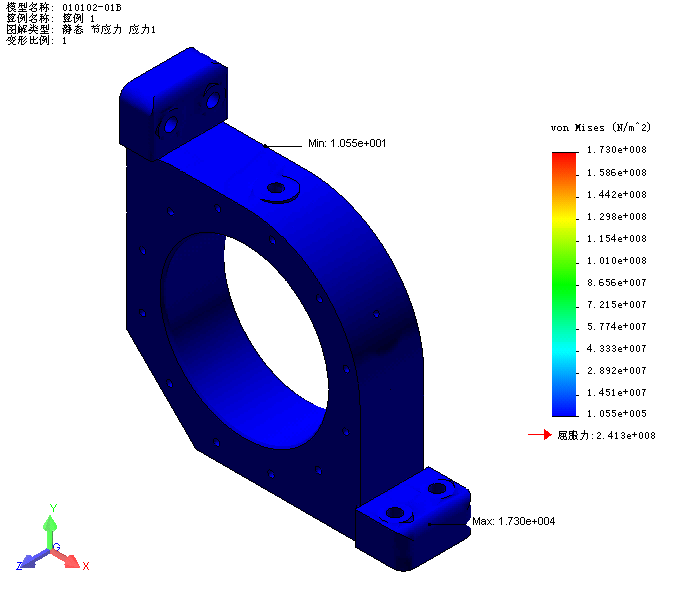

Finite element analysis

We use 3 types of software (ANSYS, Abaqus, Solidworks) to make verifying analysis to each key component including the finite element analysis of machine frame, drum and supporting structure, force distribution of drum body and shaft, and safety value of bearing seat.

Programming of numerical analysis software

Force analysis for the drum is quite complex, which is mainly composed of the force of friction and positive pressure. Presently, the problem of drum shell calculation hasn’t been solved in China, and the thickness of the drum shell is completely decided according to experience, which is not scientific. Our company has cooperated with doctoral students of Tsinghua University to calculate the thickness of drum shell and ancillary plates, circumferential welding location and connecting flexibility of ancillary plates with Matlab value analysis software, of which we have the proprietary intellectual property rights. And we conduct finite element analysis to the whole drum and verify the calculation, and make sure the results of finite element analysis and numerical analysis are the same, which enable us to become the leading enterprise of drum designing.

Ø Independent software development

Professional calculation software of power, belt strength, tensile force, non-return force, braking force, dynamic loading check of roller.

Calculation software for power and tensile force of pipe belt conveyer

Calculation and verification software for drum

Calculation and verification software for machine frame

Ø Establishment of theoretical calculation system for key components

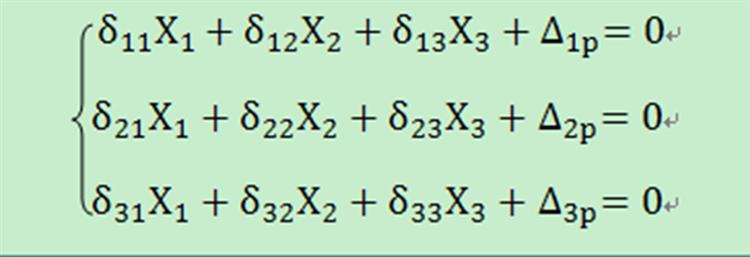

Theoretical calculation for machine frame

Presently, the design of most machine frames is based on experience, and there is a lack of detailed calculation. Our company has conducted optimization research on the machine frame, and combined theoretical analysis and finite element analysis, and make calculation with force and displacement methods, and program calculation software which has made our machine frame rank the top in the area of machine frame design. Regular formula is below:

Theoretical calculation for supporting structure

ß Self-weight load qz+qb+qT+qR

ß Material load qG

ß Wind load Pf=AVw^2C/1600

ß Ice & snow load Px=0.1KN/m^2

ß Earthquake load is considered as special load in calculation

Theoretical calculation for drum

1.Drum surface

Based on the results of finite element calculation, normal stress at the axial direction on the near restrained end is very small no matter it is 35° or 180° loading. Therefore, we can consider the drum shell as pin-ended.

Theory of plates and shell

The cylindrical-coordinate system is adopted, and x is axial length (dimensionless axial length α=x/a), β is the angle at the circumferential direction, z is radial direction.

Basic assumption for shell: normal vertical force on the middle face of shell is very small; shearing force between normal direction and any other direction in the middle face (i.e. εxz�, εβz) can be neglected; the normal force on the parallel section of the middle face (radial normal force) is much less than the vertical normal force (axial and circumferential direction) which can be also neglected.

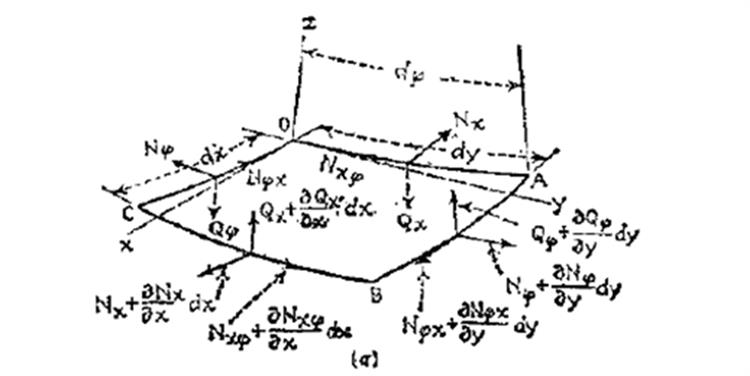

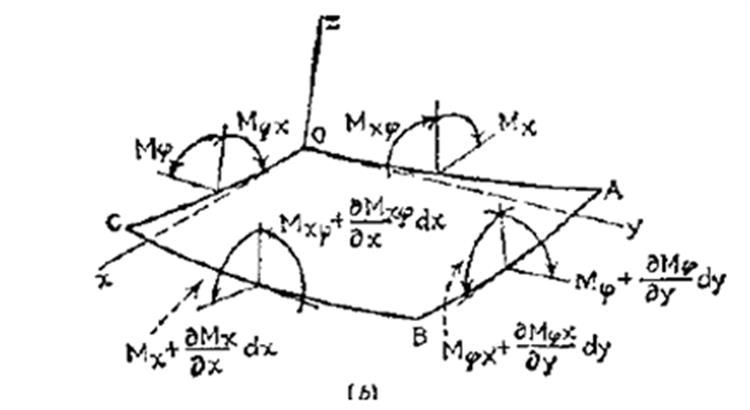

Mechanic identification: N���x, ��Nβ is axial and circumferential membrane force, M�����x�, Mβ is axial and circumferential bending moment; M�����xβ is cross section torque; Q���x�, Q�β is vertical shearing force on the axial and circumferential cross section; �S���xβ�, S���βx is vertical heave force on the axial and circumferential cross section as below.

Technical Equipment

We are equipped with complete processing and manufacturing system of casting, forging, processing, heat treatment and welding. Currently, we have 1366 (sets) manufacturing equipment and a production line of roller with annual production capability of over 400,000 sections.

|