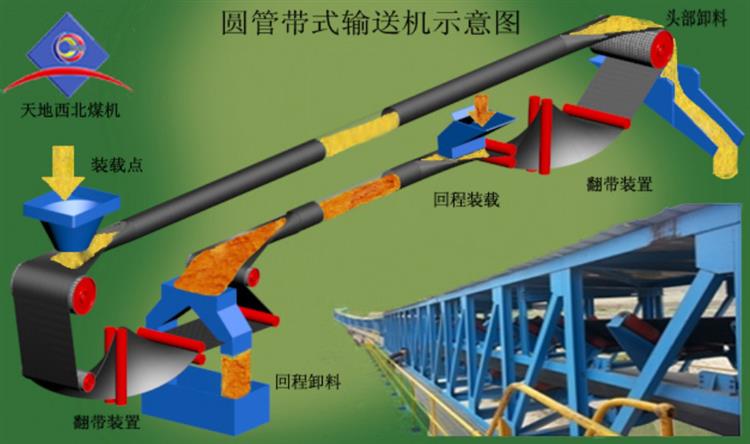

Product name: round tube belt conveyor

Product introduction: round tube belt conveyor is new type belt conveyor, it developed from conventional channel belt conveyor, and it is special belt conveyor. Belt open as channel shape at loading and discharge area, after loading and discharge, belt will be shaped into round by shiatsu roller, when it becomes round tube, the roller which set as hexagon force it stay as tube. Because the belt stay as tube during transportation, the material will not falls, and also will not affect by wind, rain or other external environment, it also could avoid the spill of material to pollute the environment, also avoid the contamination from external environment, to achieve fully closed transportation.

Detail content: round tube series belt conveyors are suitable for variety of complex ground condition, the density of conveying material usually 0.5~2.5t/m3; use normal round tube belt conveying machine, the working temperature is -25℃~+40℃; for heat resistant, cold resistant, anti-corrosion, flame proof, inflame retarding requirements, it will be special round tube belt conveyor, working temperature is -35℃~+110℃. This series product widely use for power plant, construction, chemistry, mining, metallurgy, port, coal, grain etc industries material conveying.

The feature of round tube belt conveyor

(1) Clean conveying

(2)Compact structure

(3) Easy turning space

(4) Double direction transportation

(5) Large inclination transportation

(6)Reduce the investment cost

The bending radius of round tube belt conveyor

|

Name

|

The bending radius of round tube belt conveyor

|

|

Nylon canvas belt

|

Steel core belt

|

|

Horizontal bending

|

D×300

|

D×700

|

|

S-bending

|

D×400

|

D×800

|

|

Concave

|

D×300

|

D×700

|

|

Convex

|

D×400

|

D×800

|

|

Space bending

|

Horizontal+ concave bending

|

D×400

|

D×800

|

|

Horizontal + convex bending

|

D×500

|

D×900

|

the table of round tube belt conveyor parameters (tube diameters, belt speed, conveying capacity)

|

v,m/s v,m/s

Iv m3/h

D,mm

|

0.8

|

1

|

1.25

|

1.6

|

2

|

2.5

|

3.15

|

3.5

|

4

|

4.5

|

5

|

Open belt width

|

(mm)

The belt width of relevant common belt conveyor with similar capacity

|

(mm)max particle

|

|

150

|

29

|

36

|

45

|

57

|

72

|

|

|

|

|

|

|

530

|

350~450

|

50

|

|

200

|

55

|

69

|

86

|

110

|

137

|

172

|

|

|

|

|

|

700

|

500~550

|

65

|

|

250

|

90

|

112

|

140

|

179

|

224

|

280

|

353

|

|

|

|

|

900

|

600~650

|

80

|

|

300

|

133

|

166

|

208

|

266

|

332

|

415

|

523

|

|

|

|

|

1050

|

700~

|

100

|

|

350

|

185

|

231

|

289

|

369

|

462

|

577

|

727

|

808

|

|

|

|

1250

|

750~800

|

115

|

|

400

|

245

|

306

|

383

|

490

|

612

|

765

|

964

|

1071

|

1224

|

|

|

1450

|

850~900

|

130

|

|

450

|

|

392

|

490

|

627

|

784

|

980

|

1234

|

1372

|

1568

|

|

|

1600

|

950~1000

|

150

|

|

500

|

|

|

610

|

781

|

977

|

1221

|

1538

|

1709

|

1953

|

2197

|

|

1800

|

1050~1100

|

165

|

|

550

|

|

|

|

953

|

1191

|

1488

|

1875

|

2084

|

2381

|

2679

|

2977

|

1950

|

1150~1200

|

180

|

|

600

|

|

|

|

1141

|

1426

|

1782

|

2246

|

2495

|

2852

|

3208

|

3565

|

2150

|

1250~1300

|

200

|

|

650

|

|

|

|

1346

|

1682

|

2103

|

2650

|

2944

|

3365

|

3786

|

4206

|

2300

|

1350~1400

|

215

|

|

700

|

|

|

|

1568

|

1960

|

2450

|

3087

|

3430

|

3920

|

4410

|

5045

|

2500

|

1450~1500

|

230

|

|

800

|

|

|

|

2063

|

2579

|

3224

|

4062

|

4513

|

5158

|

5803

|

6448

|

2850

|

1550~1650

|

265

|

|

850

|

|

|

|

2336

|

2920

|

3650

|

4599

|

5110

|

5840

|

6571

|

7301

|

3050

|

1700~1750

|

280

|