Lateral Bending Belt Conveyer

1.1The problem for belt conveyer is that the layout of the conveyer is not straight, and stage loader is needed for coal conveying, which would affect the benefits, conveying efficiency and reliability. However, the use of lateral bending conveyer can avoid those problems in some respects.

The problem for belt conveyer is that the layout of the conveyer is not straight, and stage loader is needed for coal conveying, which would affect the benefits, conveying efficiency and reliability. However, the use of lateral bending conveyer can avoid those problems in some respects.

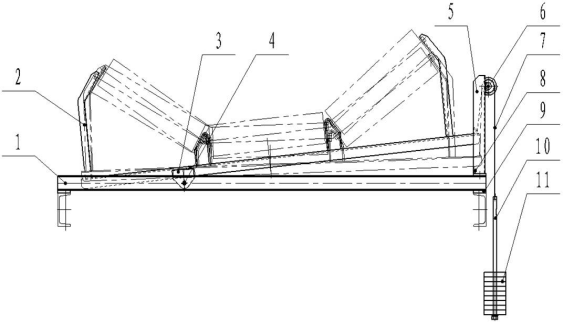

1.2 Balance weight adjusting structure

The function of this structure is that the conveyor can adapt to variable load, and realize small lifting angle when loaded, and large angle with no load. The force of balance weight can be kept stable with the principle of pulley. The Company has applied for patent for utility models as to this structure, and the defect is that additional investment is needed.

2.Advancing and Semi-advancing Conveyer

Conditions of technology development at home and abroad

There are many manufactures of the conveyer, such as SANDVIC, Krupp, TAKRAF, MMD and so on. All of those companies have the general contracting ability of continuous and semi-continuous technology for open cut mine. Structural components of those foreign conveyers are often made by domestic entrusted manufacturers because manufacturing cost is high overseas.

Technology of belt conveyor is not as demanding as other mining equipment. Main manufactures in China are Northern Heavy Shenyang Mining Machinery Group Co.,Ltd, Yankuang Group Mainland Machinery Co., Ltd, Tangshan Mining & Metallurgical Mining Machinery Plant, Hengyang Conveying Machinery Co., Ltd, etc. Presently, domestic enterprises haven’t commanded the core technology, and most of them lack the independent research and development ability.

Our company has commanded the ability of independent design, research & development and manufacture of advancing and semi-advancing belt conveyer.

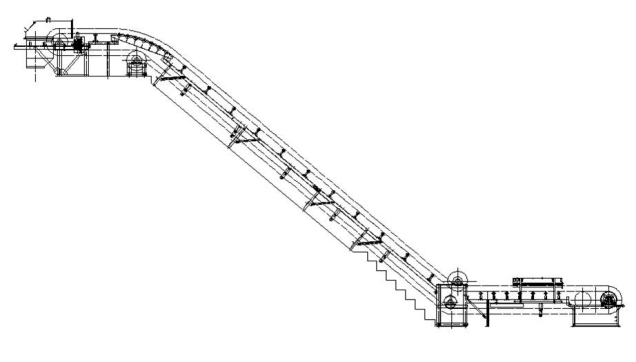

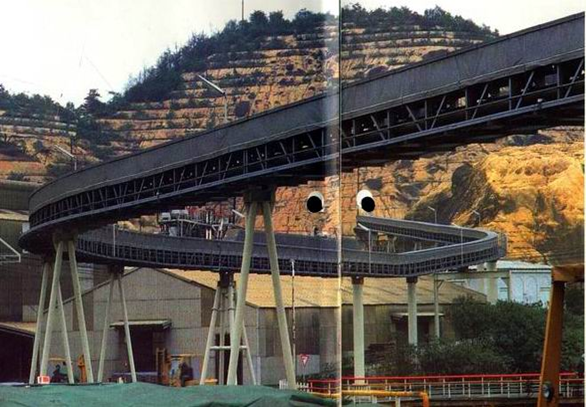

2.1Advancing/Semi-fixed DT1118 Belt Conveyer for Inner Mongolia Baiyinhua Coal Mining System.

Parameters:

Belt width: 1.4m; Conveying capacity: 3000t/h; Conveying distance: 885m; Belt speed: 4m/s; Elevation height: 170m; Power: 3x630kw.

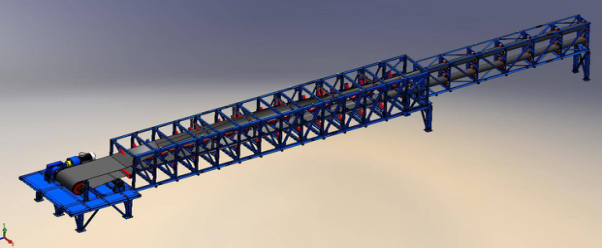

2.2Advancing/Semi-fixed Belt Conveyer for the split system of Shanxi Pingsuodong Opencast Coal Mine.

Parameters of B1301 Advancing Belt Conveyer:

Belt width: 1.8m; Conveying capacity: 9000t/h; Conveying distance: 1780m; Elevation height: 8m; Belt speed: 5.6m/s; Power: 3×1400kw.

3.Corrugated Guard Conveyer:

The corrugated guard conveyers designed by our company have been used in many

coal mines, and our designing ability has matured.

The sketch above is the corrugated guard conveyer designed by our company for Mining Corporation of Chalco Hengtai Limited

Parameters: B=650mm; Q=70t/h

V=1m/s; Dip angle α=40°, L=420 m

4.Pipe Belt Conveyer

4.1The technology of pipe belt conveyer is all from Japan.

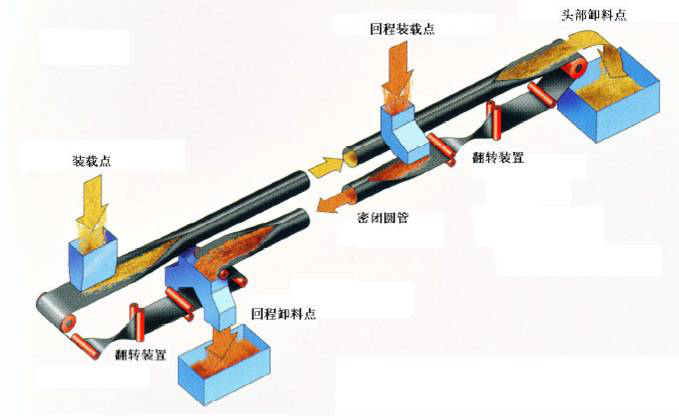

Pipe belt conveyer is a new special belt conveyer developed from traditional slot type conveyer. The belt would open like the slot type at the feeding and discharging places, and then it would be pressed by rollers to form a pipe after feeding and discharging, and the pipe shape would be kept by the rollers laid hexagonally. Therefore, materials inside the pipe would not scatter outside, and it would be kept from the interference of outside environment such as wind and rain. Thus the environment would not be influenced by the scattered materials. Enclosed conveying with no leakage can be realized.

The pipe belt conveyer can be flexibly laid out according to practical geological conditions. It can be used to convey materials in a long distance under complex geological conditions. Compared with traditional belt conveyer, it has advantages of low cost, reliability, safety and efficiency etc.

4.2Working Principle of Pipe Belt Conveyer

discharging point, tensioning device etc of the pipe conveyer are the same with those of ordinary conveyer. After the feeding is received at the tail, the conveyer would be formed into the shape of a pipe at the transition section and then convey the materials enclosed. Then the pipe conveyer would extend like a slot at the transition section of the head and discharge materials at the head.

4.3 Requirement for Pipe Belt Conveyer

The pipe belt conveyer is similar to ordinary conveyers; however some important technologies have been used for design. The pipe belt conveyer must be designed with a special frame to meet the requirement of rigidity and flexibility. The rigidity should allow it to be formed into the pipe shape and keep this shape when passing roller sets; the flexibility should allow it to pass the transition sections, and the pipe belt conveyer should form the pipe shape and pass the drum flatly to discharge materials, which can be fulfilled by adding a rubber layer in the conveyer.

4.4Advantages of pipe belt conveyer

The pipe belt conveyer can make turns at the horizontal and vertical planes, and also turns simultaneously at the horizontal and vertical planes. The maximum horizontal bending angle is 90 degrees, and the minimum bending radius is 300 times of the pipe diameter.

The pipe belt conveyer has little effect on the environment. The pipe belt conveyer is normally enclosed to conveyer materials, which would not pollute the environment, and the cost of conveying gallery can be saved as well.

The conveyed materials can be kept away from rain and wind.

The pipe belt conveyer has little effect on the environment. The pipe belt conveyer is normally enclosed to conveyer materials, which would not pollute the environment, and the cost of conveying gallery can be saved as well.

The conveyed materials can be kept away from rain and wind.

Suitable for complex geology conditions such as long distance, steep and bending. It is economical and practical, and suitable for power plant, port, underground and mine with complex geological conditions.